How the μ series ultrapure water equipment achieves high cost effectiveness

μ (mu) series is an ultrapure water equipment that connects directly to tap water, designed for laboratories focused on fields of analysis and research.

It approaches the long-sought ideal of a single unit offering cost effectiveness that overturns the conventional image of ultrapure water equipment as expensive.

Reason 1: Simple design makes the equipment unit low-priced!

μ series is equipped with only the features truly needed in an ultrapure water equipment.

- Simplified water dispensing through the omission of detailed flow control features

- Simplification of display panel to “Water quality,” “Water temperature,” and “Water tank level” only, with a touch of the “DISPLAY” button switching among the content

- Minimum necessary number of buttons on the Control Panel

Water dispensing features include a quantitative water dispensing function capable of storing up to three water dispensing patterns.

See the µ series lineup webpage for details on other features and specifications.

Reason 2: Dual consumable cartridges for the pure water component and the ultrapure water component reduce maintenance costs to about half of conventional costs

Multiple water treatment processes are required to produce ultrapure water, taking place in two stages: production of pure water from tap water, followed by production of ultrapure water from pure water.

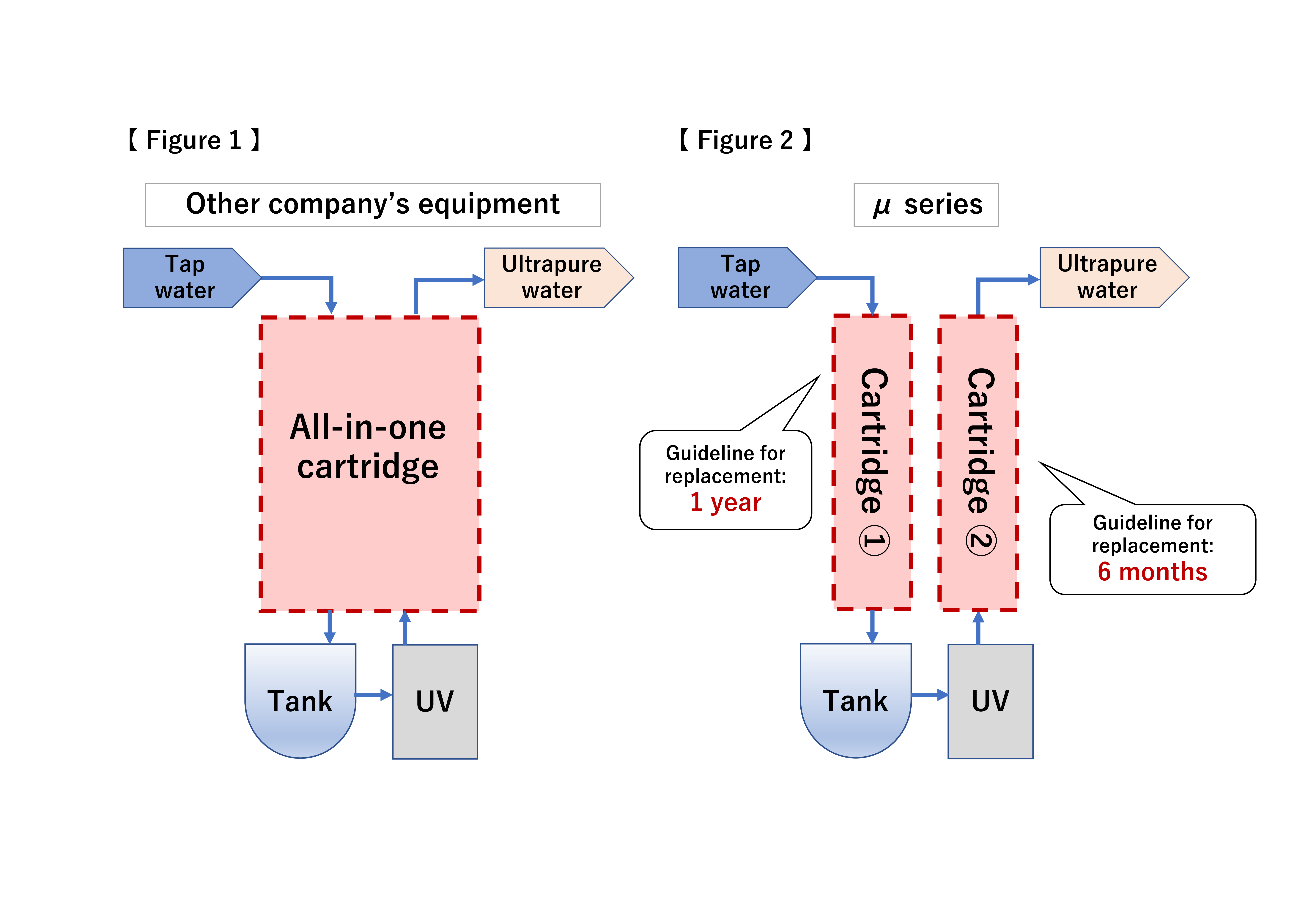

As shown in Figure 1, when cartridges are integrated into one, the ability to replace the consumables all at once appears economical.

In actuality, however, as different water treatment elements are used in the pure water production component and the ultrapure water production component, the periods between replacements differ.

Accordingly, in the case shown in Figure 1, consumables are replaced without having demonstrated their full capability, with the result of high maintenance costs and wasted resources.

Conversely, by separating the consumable cartridge into two, the μ series in Figure 2 allows each cartridge to be used up to the end of its capabilities and without waste, keeping down running costs.

While the guideline for frequency of pure water production component replacement is one year, that for ultrapure water production component replacement is a more frequent six months.

This is to maintain the quality of ultrapure water.

Moreover, as tap water quality varies by region and season, the use of two cartridges enables adjustments for poor water quality, such as higher-than-normal replacement frequency of the pure water production component. Naturally, the replacement of two consumable cartridges is necessary, but you can rest assured that the replacement process is simple.

View a video of consumable cartridge replacement here.

Summary

We hope this video has been helpful in understanding ultrapure water equipment.

We have shown how the μ series ultrapure water equipment achieves high cost efficiency.

- Simple design makes the equipment unit low-priced!

- Dual consumable cartridges for the pure water component and the ultrapure water component reduce maintenance costs to about half of conventional costs

Please contact the below with any questions about the equipment.